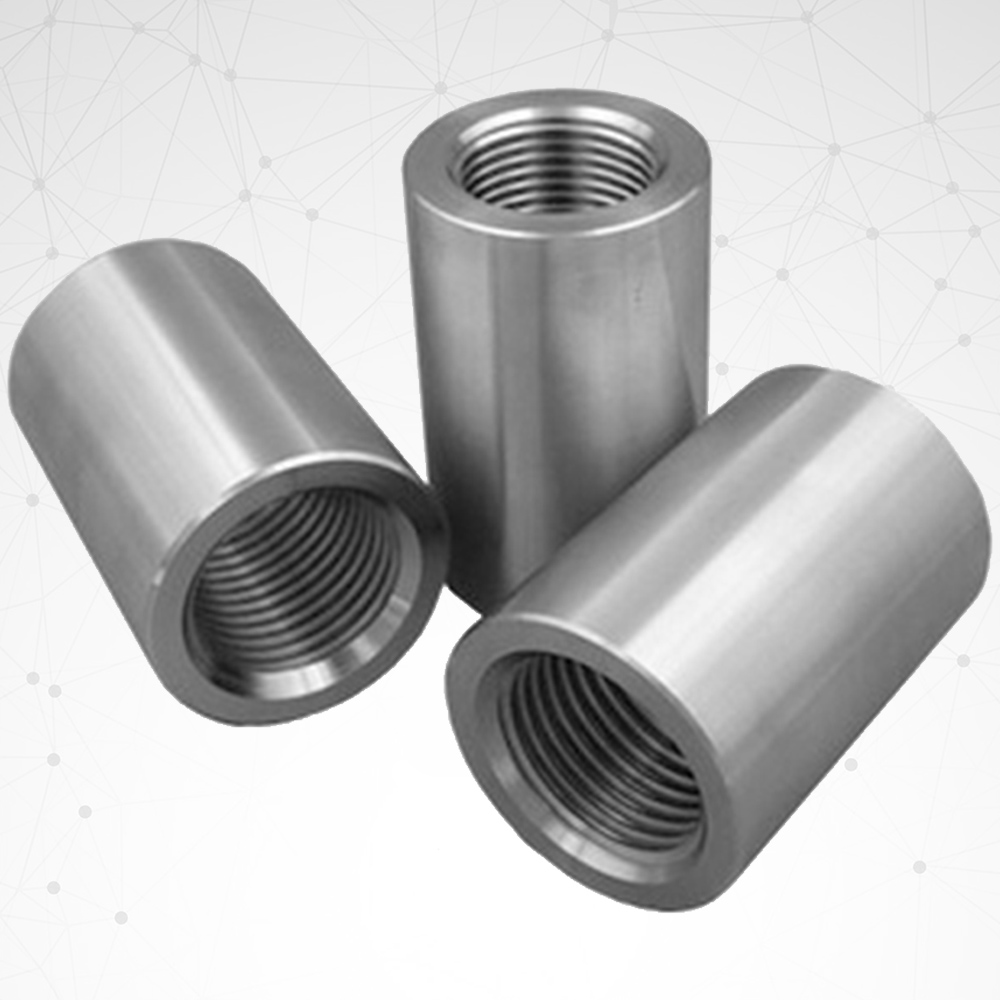

Rebar Cold Forged Coupler is a full tension splice, This Coupler maintains the full ductility of reinforcing TMT bar. Rebar Cold Forged Couplers is a parallel threaded mechanical splicing system designed for the connection of TMT Bar from 16mm to 40mm.

| Category | Rebar Coupler |

| Stocks | 100000 |

| Share | |

| Contact Us | Call Now |

Rebar Cold Forged Coupler is a full tension splice, This Coupler maintains the full ductility of reinforcing TMT bar. Rebar Cold Forged Couplers is a parallel threaded mechanical splicing system designed for the connection of TMT Bar from 16mm to 40mm.

| Bar Diameter (mm) | 12 | 16 | 20 | 25 | 32 | 40 |

| External Diameter (mm) | 21 | 28 | 32 | 40 | 50 | 62 |

| Coupler Length (mm) | 32 | 40 | 48 | 60 | 72 | 90 |

| Thread Size | M16 | M20 | M24 | M30 | M36 | M45 |

| Thread Pitch | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 |

| Weight (Kg) | 0.04 | 0.09 | 0.16 | 0.32 | 0.58 | 1.13 |

| Bar Diameter (mm) | 12 | 16 | 20 | 25 | 32 | 40 |

| External Diameter (mm) | 20 | 25 | 32 | 40 | 50 | 62 |

| Coupler Length (mm) | 30 | 36 | 44 | 50 | 64 | 80 |

| Thread Size | M14 | M18 | M24 | M29 | M36 | M45 |

| Thread Pitch | 2.0 | 2.0 | 2.5 | 3.0 | 4.0 | 4.5 |

| Weight (Kg) | 0.04 | 0.08 | 0.15 | 0.28 | 0.53 | 1.00 |

Find some related products & explore the categories for better experience which you like it.

Rebar couplers are employed in reinforced concrete cement structures to change the system of lapping & welding in reinforcement. Rebar ...

View Product

Surya Engineering is a Leading Manufacturer of Reinforcement Bar Coupler. Surya Engineering Deals in Mechanical splicing system ...

View Product